Innovation often begins with a bold question. For neustark, it was this: what if concrete could store carbon instead of emitting it?

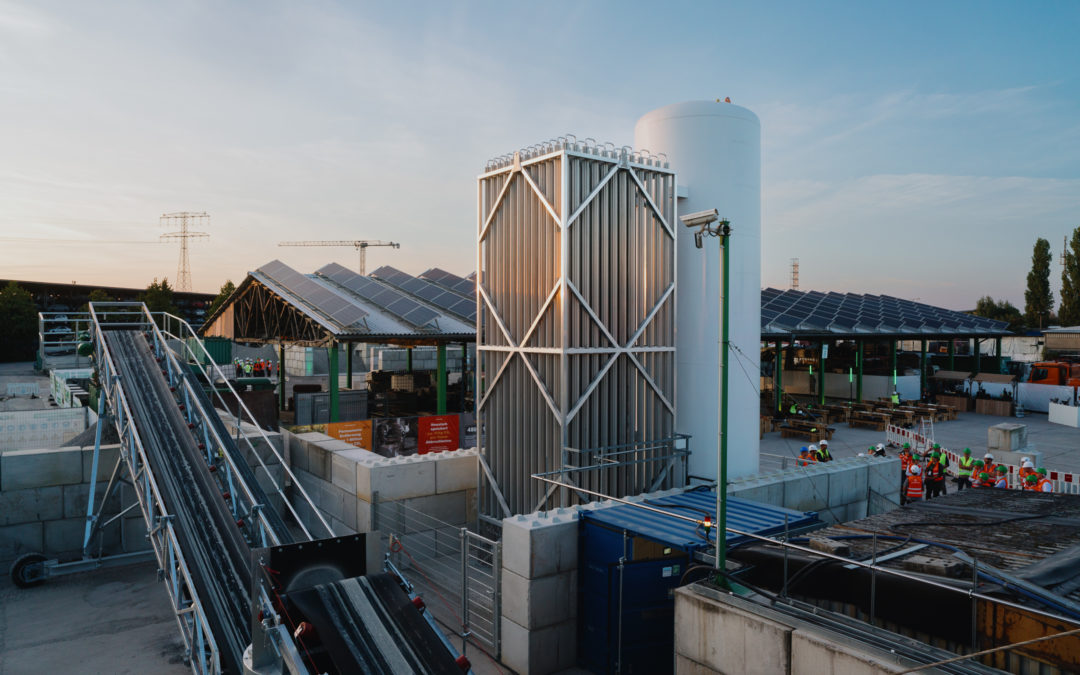

Today, neustark is doing exactly that. Their carbon removal technology permanently binds carbon dioxide into processed demolition concrete. What sounds like science fiction is already happening at recycler sites in Switzerland and other parts of Europe. After the material has been enriched with carbon dioxide, it is used in concrete production, which usually happens at the same site as the recycling process. With support from WSP, UBS and the Boost My Startup Challenge, neustark’s solution is growing in visibility and scale.

We spoke with Elmar Vatter, Project Lead at neustark to hear more about their journey and what lies ahead.

From Startup to Impact Partner

Since winning the Boost My Startup Challenge in 2024, neustark has extended its operations across central Europe. They now have 34 capture and storage sites in Switzerland, Liechtenstein, Austria, France, Germany, Italy and the United Kingdom. Their technology is used to inject carbon dioxide into demolition concrete. The material often ends up in road construction or recycled concrete, although neustark’s primary goal is carbon removal. What happens to the material after carbonation is outside their direct focus.

In terms of public sector uptake, Elmar sees room for progress. “Carbonated recycled concrete is still a new material,” he explains. “Public clients are often reluctant to be the first to adopt something unfamiliar. That hesitation is something we are working to address.”

This is where the collaboration with WSP and UBS makes a meaningful difference. WSP brings access to infrastructure projects, in-depth engineering expertise and a clear understanding of planning and permitting environments. UBS contributes financial insights, access to investor networks and tailored growth support.

“The collaboration with WSP and UBS is both strategic and hands-on,” says Elmar. “It has helped us move faster and think beyond our current scope.”

Eyes on the Highway

Neustark’s ideal project would be a one-kilometre section of Swiss highway where their material is used in the frost protection layer and gravel base course. The project would be technically achievable and environmentally significant. More than that, it would serve as a high-profile example of climate action in infrastructure.

“If we can make this happen on a Swiss Autobahn, we can do it anywhere,” Elmar says. “It would show what is possible when innovation meets ambition.”

Scaling Smart and Staying Grounded

Neustark’s model is built for practical scalability. Their system captures carbon dioxide from nearby wastewater treatment plants and injects it into processed demolition material. This approach uses local waste streams, keeps transportation minimal and fits easily into existing workflows. It is compact, energy-efficient and ready to deploy at scale.

Next on the agenda is working with additional types of mineral waste, such as slags, ashes and incinerator bottom ash. At the same time, neustark continues to build trust with regulators and public stakeholders. The goal is to show that carbon dioxide removal technologies are not only feasible but already available and ready to use.

Neustark’s work is a powerful example of what can happen when technology, purpose and the right partnerships come together. With the support of WSP and UBS, they are showing that sustainability can be more than a vision. It can be something we build, today.