Green hydrogen projects are an important asset in the race to zero emissions. A hypothetical case study explores the viability of green hydrogen projects in the actual market. BG Consulting Engineers SA (BG) and the startup Sympheny put together real-world experiences and high-tech solutions to assess the economic and environmental benefits of producing green hydrogen for heavy mobility in Switzerland.

Motivation and Objective

The recent energy shortages in Europe reminded us how important energy independence is, especially for a landlocked country like Switzerland. Increasing the share of locally produced renewables, in particular solar PV and wind power has become a matter of national security. However, the intermittent and seasonal nature of PV and wind poses a challenge that has yet to be solved. A possible solution is to transform excess renewable electricity into Green hydrogen, a stable chemical energy carrier that can be stored for long periods. In Switzerland, the projected major uptake of green hydrogen is heavy mobility, which is one of the most difficult sectors to decarbonize.

There are two major dilemmas concerning green hydrogen:

- The competition for renewables: producing one kg of hydrogen with an electrolyzer requires approximately 10 liters of water and 50kWh of electricity. The Swiss electric grid currently relies, in part, on fossil fuels. Therefore, the use of renewable electricity to produce green hydrogen might lead to a competition for renewable energy resources.

- The cost of production: the cost of producing one kg of green hydrogen is high. Resources available for decarbonization are limited. The current price point for one ton of avoided CO2 emissions is about 100 CHF[1]. The cost of emissions reduction is a good indicator for decision making in a feasibility study.

BG, in collaboration with the Paris Université des Arts et Métiers and the Swiss startup Sympheny, set out to test these dilemmas and answer the question: does it make economic and environmental sense to produce green hydrogen for heavy mobility in Switzerland in 2023?

Background of the case study

To answer the question, a hypothetical case study was conceptualized based on the vast experience of BG in the energy, building and industry sectors. The conceptualized case study, with complex technology combinations, presents infinite possible system configurations.

How do we determine the optimal size and operation of each part of the system to minimize costs and emissions? To answer this question, we combined engineering expertise of BG and advanced computational tools developed by Sympheny, a powerful energy system optimization software that explores thousands of possible solutions and identifies the optimal solutions within minutes.

The model was configured in Sympheny based on several real-world experiences based on BG’s projects. Among other multi-energy, hydrogen, energy storage and decarbonized mobility projects, BG did a feasibility study to decarbonize the 1’000-vehicle fleet of a French region, including hydrogen for heavy mobility. BG also contributed to one of the few live hydrogen projects in France, a remote antenna powered by solar power, with battery and hydrogen-based power storage.

Case study description

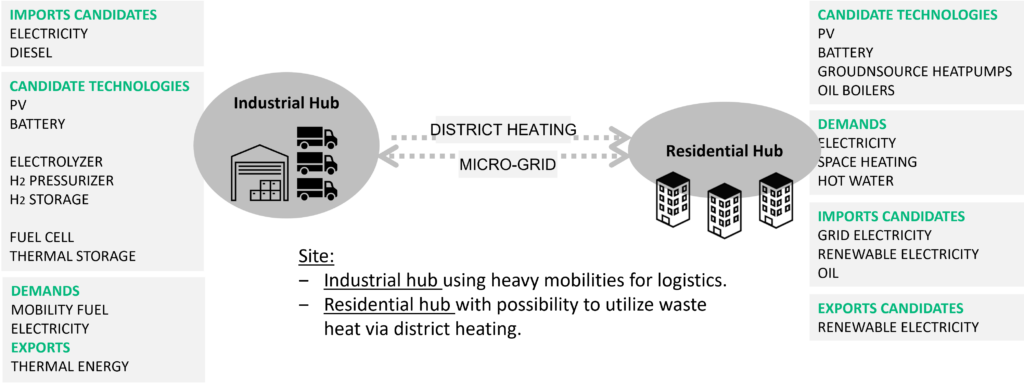

The case study includes two sites. The first site is an industrial hall with 20’000 m2 of roof surface available for solar PV installation, and a fleet of 200 long-haul diesel trucks. Hydrogen is produced using on-site solar power. A renewable energy-powered battery increases the operating hours of the electrolyzer. The hydrogen is stored at 700 bars in high pressure tanks connecting to a hydrogen fueling station. Part of the truck fleet is refurbished to run on hydrogen.

The second site is residential, not far from the industrial site, to take advantage of the waste heat from hydrogen production. It is an interesting sector-coupled solution to increase economic viability of hydrogen production.

In total, the considered multi-energy system consists of 8 technology candidates spread over two sites which are linked by district heating, such as shown on figure 1.

Results

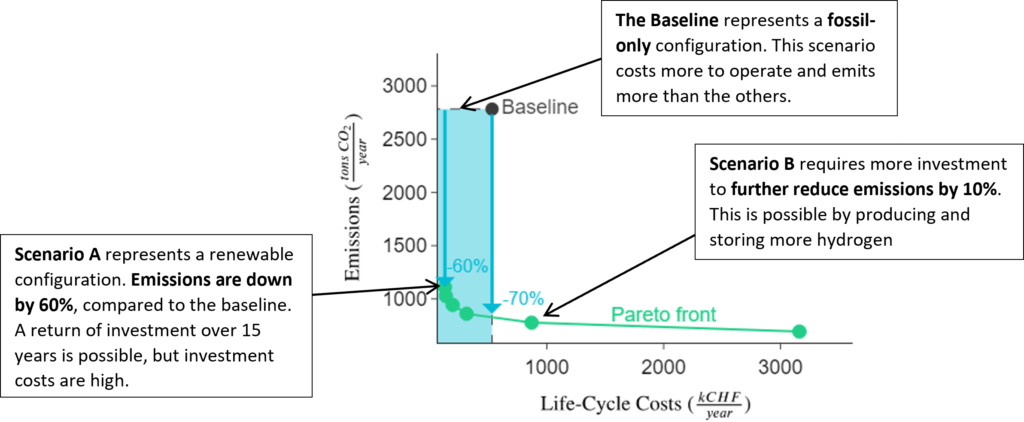

Sympheny’s software provides different graphs and illustrations to easily navigate the optimization results. The results show multiple optimal configurations with a clear cost and emissions trade-off. Figure 2 shows multiple optimal solutions ranging from the most economically viable to the most environmentally friendly. The cost and emission of the baseline, a fossil-only configuration, is not on the Pareto front, because both costs and emissions are higher.

Conclusions

We have demonstrated how the collaboration between BG and Sympheny allowed to tackle an emerging problem efficiently and effectively by incorporating novel solutions with real-world expertise over multiple decades in all fields of engineering and high-tech solutions.

Despite the current high investment costs for hydrogen systems, with promotion by state funding and private developers, the market is evolving faster than ever. It is why BG has been actively pursuing hydrogen projects during the last decade, developing valuable skills and relationships to decarbonize our economy.

Nils Ter-Borch,

BG Ingénieurs Conseils SA, for the Boost My Startup Challenge

[1] klik.ch/resources/KliK-Foundation_Annual-Report_2021.pdf